How does laser engraving service work?

- Creation of ideas

- Design image for the marking

- Choose the material

- Set up the laser engraving machine

- Laser engraves the design

Our customers often wonder how we conceptualize, create, and sell our spectacular and high-quality trophies, medals, plaques, signages, keychains, and other metal engraving products that we offer for schools, corporate events, special award ceremonies, and so on.

In this blog, we will show you how El Oro’s laser engraving service works to give you a glimpse of how we create one-of-a-kind customized awards, trophies, and gifts. Keep reading!

What Is Laser Engraving?

Laser engraving is undoubtedly the most popular laser marking technology that we are using to put marks, identification, and traceability on our trophies, awards, plaques, and other products we offer. This process leaves highly accurate and fine permanent markings by using a laser engraving machine to help vaporize specific areas on our materials.

Laser engraving is the best process and is highly reliable for putting traces, designs, and logos for medals, trophies, plaques, signages, and so on.

How Does Laser Engraving Service Work?

Before we go to the laser engraving process to create high-quality and affordable personalized awards, medals, and such, we create the design first, and then we’ll start the process once approved by our customer.

Creation of ideas

In this initial process, ideas are conceptualized and created to find the best materials that suit our customer’s needs. Here at El Oro, we make sure to come up with relevant ideas with high creativity because we believe that these two are the most crucial part of the laser engraving process — because they motivate the entire quality of the markings and once the design has been marked on the metal, it cannot be changed.

Design image for the marking

After the creation of ideas has been made, it’s time to transfer them to computer software. There is plenty of available graphics software for designing such as Adobe Illustrators to create graphic designs for awards, trophies, plaques, and such.

Our expert team has intensive knowledge of complementing the designed file with our laser engraving machine to ensure that the result will not affect the quality and size of the design once marked on the material used.

Choose the material

The third step is choosing the best material that’s compatible with the laser engraving machine that matches your design. Generally, a laser engraving machine works with materials such as glass, wood, metals, plastics, and stones.

Here at El Oro, we also add organic materials when creating medals, trophies, awards, and so on to make sure that our laser markers will leave permanent and fine markings and designs.

Set up the laser engraving machine

Every material has a different laser engraving process that’s why it is a requirement to set the cut depth, laser strength, speed, line thickness, and number of passes to test the materials and see their effects after the process. Once the testing is done, we’ll store the best settings to ensure that the result will reflect what our customer wants.

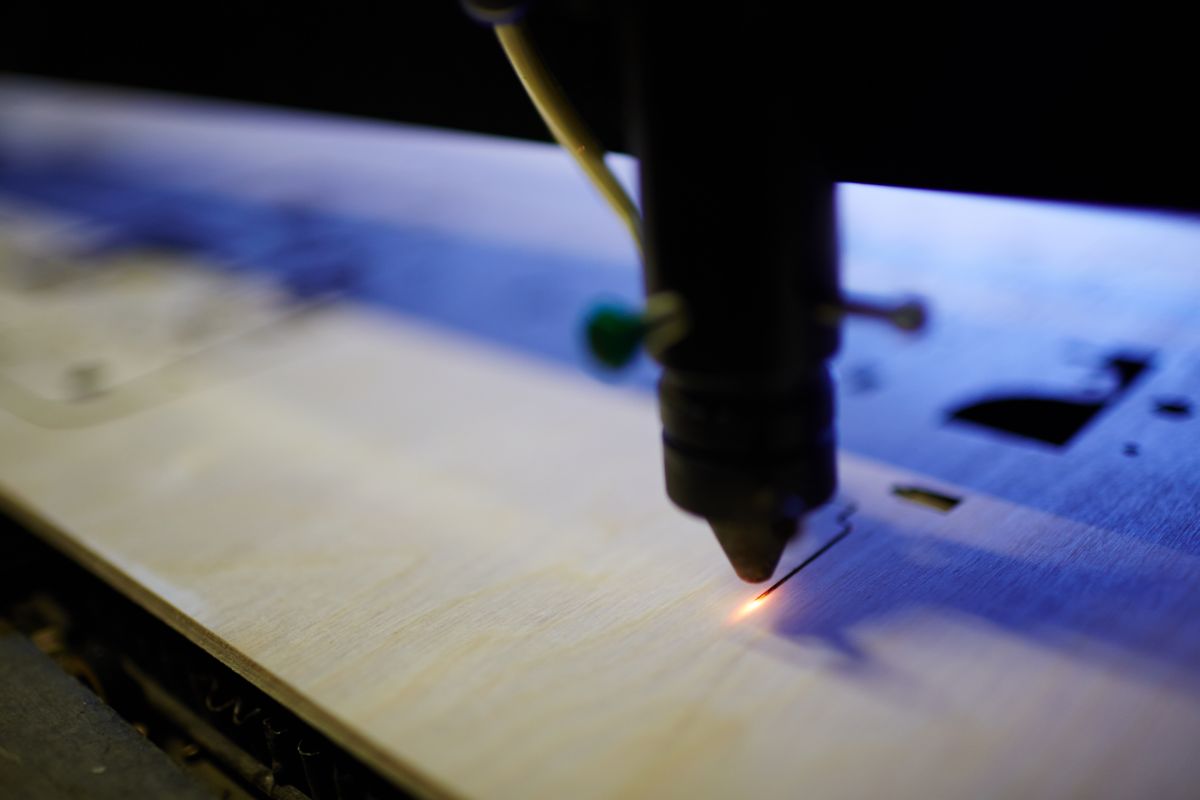

Laser engraves the design

Once the concept of ideas, design, and testing is done, the laser engraving process will finally take place. What happens is the material will be placed in the machine for permanent markings then we wait until the design has been successfully engraved by the machine. After that, we gently pull it out and make sure to clean the markings.

Materials Used For Laser Engraving Service From El Oro

Fortunately, laser engraving service is compatible with many materials. Find out what materials we use below:

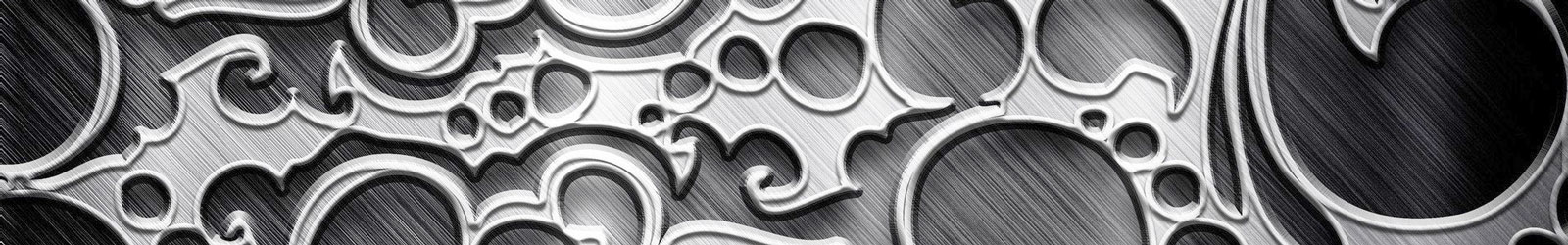

Metal

We believe that metal is the heart of the laser engraving process because they’re heavier, more durable, and allow a wide range of flexibility in terms of design. It’s a widely used material and often the best for high-quality engraved products.

Wood

As previously mentioned in this blog, wood is also suitable for the process. Here at El Oro, we also offer wooden trophies with unique and intricate designs to match our customers’ needs.

Acrylic

With the outstanding strength and optical clarity of acrylic, they are also easy to fabricate and engrave compared to other plastic materials.

Glass

Because glass is made from natural and raw materials, it is easy to melt at high temperatures which then helps to form a new design. Thus, this makes glass work well with our laser engraving service.

Key Takeaway

Now you now have an idea of how laser engraving service works here at El Oro. You’ll also have enough considerations to weigh in when opting for personalized trophies and awards for special events.

When you’re giving recognition to someone or a group of people, remember that they all deserve precise, permanent, and high-quality awards. Hence, it’s important to partner with the best one in the business — El Oro! We are renowned for our work in several types of medals and signages, including acrylic plaques in the Philippines.

Are you looking for a high-quality and affordable laser engraving service? Why not let us help you visualize your ideas to get started immediately? Contact El Oro today and we’ll surely follow your ideas and requests!

104 Years of Providing International Awards of Distinction and Quality

104 Years of Providing International Awards of Distinction and Quality